67″ Hophornbeam Bend Thru The Handle Flat Bow

- Final weight 20.4 ozs

This stave was the small half split off a HHB 4-5″ diameter tree. The stave wasn’t quit big enough for two complete staves, so this became a bend through the handle design for lack of enough material in the center for a better handle.

I decided to use it and do some experimenting and learning

This stave had a hook that made the sting center outside the handle. I heat treated just the center section while drawing it back into form. I figured this would allow the string to be closer to the handle center (although not really centered) and would stiffen the handle section of the bow

Here is a walk through of my notes. I’m looking for any thoughts or guidance, especially around why it has such bad handshake.

I quickly roughed it out and had a good floor tiller when I got to the long string. I tillered normally and was working pretty quick. At 72″ i figured I had room to pike if I made a mistake. I was shooting for 60#@28″

Being quick I hit 60#@28″ before I expected and full draw looked like this:

Spec’s at this point look like this

1 1/2″ at widest to about mid limb then tapers to .5″

72″ tip to tip

60#@28″

it has some fairly significant handshake

1 3/4″ string follow (most of that is set, although some may be soft set)

I did some trapping to cut the weight and hoped to improve the fps. It didn’t help the speed. I’ve also narrowed and lighten the tips hoping to improve the handshake. It hasn’t helped much yet.

At this stage it’s shooting at about 145fps

Then I Did some tillering with the gizmo. That helped the tillering but still has significant handshake.

Now 55# (i may pike it but waiting to improve the handshake)

After some testing i found if I shot the arrow of my knuckle at bow center I get 158fps. If I raise the arrow to 1 1/4″ above center I loose 5 fps to 153fps (this is with 10 shots of arrows ave 650gr) if I shot the arrow of my knuckle at bow 1 1/4″ below center 157fps

So the bow definitely wants the top limb to be longer(or I assume the lower limb stiffer)

Still a 1/8″ positive tiller

I then narrowed the tips down to .38″ at the nock. This was tapered to about mid limb as before.

draw weight is still reading about 55.3#@28″ Narrowing the tips brought the speed back up to 152fps. The handshake might be slightly better, but still uncomfortable.

Next day for the 67″ Hophornbeam Bend Thru The Handle Flat Bow,

I glues some leather on the handle to make it more comfortable.

I formed that into a handle

I cut 1 1/2″ off each end and recut the knocks.

Did some minor tillering and weight reduction back to just over 60#

63.8#@28″ now shooting about 159fps

Second set 63.9#@28″ now shooting about 161fps

1/4″positive tiller and most if not all of the hand shake is gone.

Did some more trapping and weight reduction from the sides

switched to a lighter string

3/16″positive tiller

No handshake

61.5#@28″ 161fps 156fps 158fps

About 2 3/8″ string follow

Did sanding, removed tools marks etc. Sanded to 320 grit

Shot about 60-70 arrows and still 150fps and reading 60#@28″

It’s turned into a reasonably pleasure to shot. It’s a little heavy for me, but I can still hold a reasonable group up to 30 yards

Final dimensions

66 1/2″ tip to tip

1 1/2″ at widest to about mid limb

tip .49″

dimensions:

Hophornbeam Bend Thru The Handle Flat Bow Dimensions

https://www.diy.timetestedtools.net/hophornbeam-bend-thru-the-handle-flat-bow/dimensions from bow center --->

| Ctr | 1 | 2 | 4 | 6 | 8 | 10 | 12 | 14 | 16 | 18 | 20 | 22 | 24 | 26 | 28 | 30 | 32 | 34 | 35 |

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| Thickness | - | - | .83 | .77 | .76 | .71 | .69 | .68 | .65 | .61 | .60 | .59 | .56 | .55 | .55 | ..56 | .56 | .56 | .49 |

| Width | 1.5 | 1.5 | 1.5 | 1.5 | 1.5 | 1.5 | 1.5 | 1.5 | .5 |

I cut another 1″ of each end bringing it down to 66 1\2″ tip to tip.

Tillered it back to just under 58#@28″.

Current average speed with my 650gr arrows is 158fps.

It’s a little more powerful than I will take hunting. I loose accuracy after about 53#, but I like to shot a heavier bow once in a while, and this one is fun to shot, and as with all I’ve built so far, it was a learning experience.

The response from http://www.primitivearcher.com/smf/index.php/topic,70563.0.html gives a good reason for the original handshake:

Simple reason for the handshock – it is bending too much in the handle/innerlimbs.

At that length the tiller should’ve been highly elliptical with virtually no bend in the middle. 1/3rd.

As you have shortened it you have effectively reduced the bend in the handle/inner limbs.

Narrow tips will help reduce handshock on a bow that suffers with it. However your tips are not the reason you have handshock. You can leave the tips 3/4″ wide and have zero handshock IF and its a big IF……..the bow is tillered correctly. Handshock is your bow telling you that it is out of tiller. Either limb balance relative one to the other is out or the tiller is wrong for your width taper

And

Making that thickness of .84 extend out a few more inches either way from the handle for a more eliptical tiller.

Shooting heavier arrows does reduce handshock a bit too making the bow more efficient with bows 5.5′ in length.To really see if a bow has no handshock shooting an 8 grain arrow will show you too.Right now your shooting around a 11.5 grain arrow.

Final after finish and shoot in:

Died with Fiebing’s Leather Dye

Finished with Minwax 630520444 Water Based Helmsman Spar Urethane

With a few coats of SC Johnson Wood Paste Wax

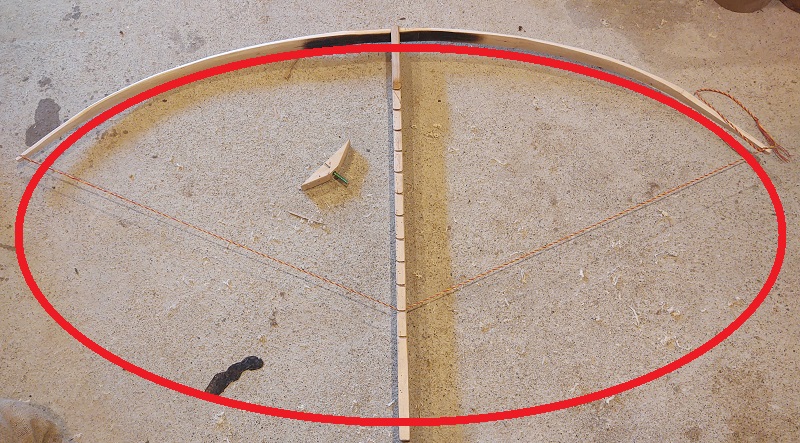

The pencil in the above image shows center. The dimensions in the follow start at the end of the handle for each limb.

Hophornbeam Bend Thru The Handle Flat Bow Final Dimensions

https://www.diy.timetestedtools.net/hophornbeam-bend-thru-the-handle-flat-bow/58#@28". 66 1/2" Tip To Tip

Current average speed with my 650gr arrows is 158fps.

The dimensions in the follow start at the end of the handle for each limb. (see handle image above)

| 0 | 2 | 4 | 6 | 8 | 10 | 12 | 14 | 16 | 18 | 20 | 22 | 24 | 26 | 28 | 30 | |

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| Thickness | .78 | .68 | .67 | .67 | .65 | .62 | .61 | .62 | .57 | .61 | .55 | .52 | .53 | .56 | .51 | ..48 |

| Width | 1.40 | 1.36 | 1.34 | 1.30 | 1.30 | 1.29 | 1.26 | 1.20 | 1.19 | 1.11 | .98 | .91 | .83 | .74 | .60 | .46 |

________________

As an Amazon associate, we earn income from qualifying purchases when you click on a link. Your link clicks help us fund our website.________________